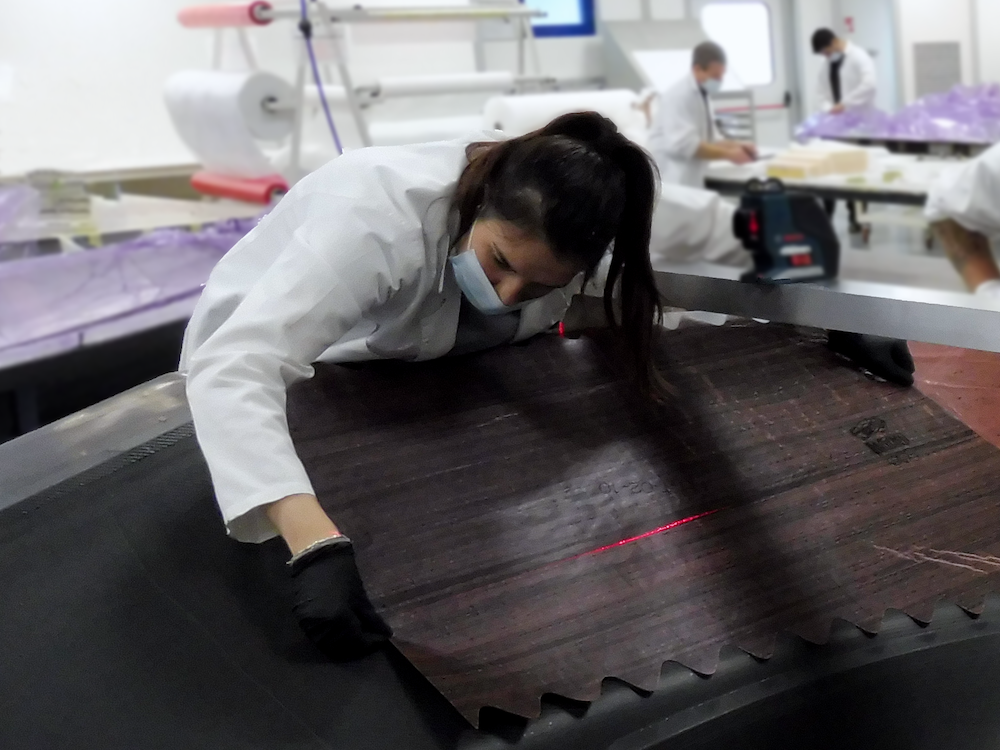

A watchmaker like Richard Mille, Solar Impulse, the solar-powered plane that flew around the world in 2005, masts and sails for America’s Cup boats and experimental hulls aiming at speed records. Since its first use in 2005, the fields of application of Carbon TPT®, a special fibre developed by North Thin Ply Technology, have been constantly expanding, allowing increasingly advanced applications in the search for strength and lightness combined with the possibilities offered by a material with a particular “manageability” in processing.

Founded as Thin Ply Technology in 2001, the company initially developed Thin Ply Technology applicable to sailmaking. Then, in 2005, it developed a “soft” composite structure for the sails of Alinghi, Ernesto Bertarelli’s team that won the 2007 America’s Cup in Valencia. After the Valencia regattas, North Sails acquired the TPT technology and the North Thin Ply Technology company was born, with headquarters in Rennes, Switzerland and a production centre in Zory, Poland.

“After Valencia and the acquisition by North,” explains Ludovic Chichignoud, chief operating officer of NTOP, “Thin Ply Technology led the industrialisation phase and later collaborated with North Sails in the new North Thin Ply Technology company for the rigid composites sector.”

“Alinghi,” continues Chichignoud, “was the initial project: the first sail made with ultra-thin unidirectional composite tapes. The ultra-thin layers were more than obvious in terms of the final thickness of the sail, but the performance gain of this thin-layer structure was much greater than expected. Thin ply technology was born, and since then NTPT has been applying this high-end technology in applications that require maximum rigidity”.

But, we ask, what are the advantages of using Carbon TPT and what are its optimal areas of use?

“Carbon TPT has several fields of use with different advantages. For non-structural parts, such as fairings and aerodynamic surfaces, we can create extremely lightweight sandwiches with very light skins. No other material can reach our strength and stiffness-to-weight ratios when it comes to lightweight sandwich structures. Applications in the world of Formula 1, in high-altitude pseudo-satellites (special drones that fly at the edge of the stratosphere, ed.), in loudspeakers or microphones for consumer electronics, but also in the wings and foils of America’s Cup boats and finally the Solar Impulse have demonstrated this very well. For structural parts, Carbon TPT is almost fatigue-free. This is really unique and allows us to reduce the safety factors during the design process to increase the workloads and reliability for critical parts.

Does the use of Carbon TPT require special rolling equipment or processes?

“No, Carbon TPT is rolled according to the standard procedure. However, by developing a dedicated process that combines the particular area of use and the properties of Carbon TPT, it is possible in most cases to amplify the qualities of the material as demonstrated by the uses made by Richard Mille Watches, in the TPTGolf Shafts and the SP80 project (the Richard Mille-sponsored project of assaulting 80 knots of speed with a particular kite-sail hull currently under construction at Persico Marine, ed).

Is Carbon TPT the only North Thin Ply Technology product?

“No, Carbon TPT is not the only product for North Thin Ply Technology. We process all kinds of fibres, from Kevlar to PBO, from quartz to glass fibres and others. For example, our quartz fibre, QuartzTPT, is a highly engineered product and widely used in Richard Mille watch cases. But we are constantly looking to improve the production process and offer the best quality and new solutions to the market. Our research and development is very focused on Richard Mille watches and golf shafts, but we are also investing a lot of work for each customer and for any application to which North Thin Ply Technology’s material can add further value”.

Emilio Martinelli